Morozoff. Limited.

The visualization of pallet movement data – showing where and how many, in real time – was smartly achieved using "epal"

* The information is used from the time of publication in November 2010.

* Company names and product names mentioned are registered trademarks or trademarks of their respective companies.

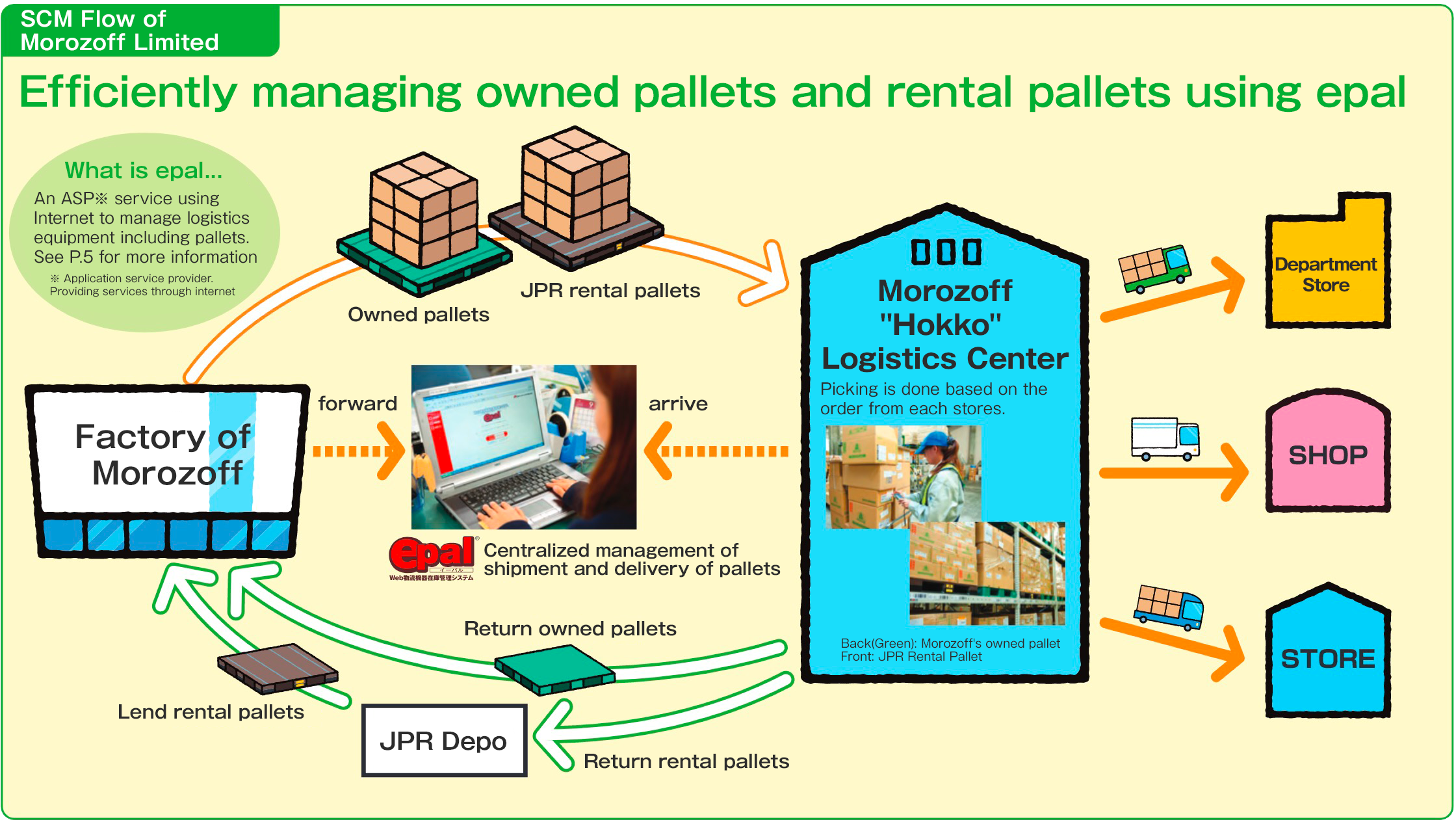

Morozoff. Limited. has been operating its own 1,100 x 700 mm skids. Upon opening the North Port Logistics Center in 2009, they decided to outsource logistics operations to Konoike Transport Co.,Ltd. Taking this opportunity, they switched to the industry standard type 11 pallet and also introduced JPR's web logistics equipment inventory management system "epal" as the management tool. Around a year after the operation started, we interviewed them for their impressions and opinions of "epal".

From left: Mr. Hiroshi Nabeta, General Manager of Logistics Department

Mr. Shinichiro Hamada, Manager of Logistics Department Sales Division, Morozoff. Limited.

"epal" is very convenient for balancing owned and rented pallets.

Morozoff. Limited.

It's been a year since we introduced our own type 11 pallets, rented pallets, and "epal". I think that it is not the time to question the pros and cons of the service for now, but the time to take the first step towards improving for the future. Looking at the data managed by "epal", we were able to see clearly the number and the time of use for both owned pallets and rented pallets.

Since our products are subject to seasonal fluctuations, we often deploy rented pallets during the busy season when our owned pallets are short in supply, and it became obvious whether there was any waste in the allocation.

In the future, with this base data, we would like to make a pallet demand forecast while balancing our owned and rented pallets.

“Epal” leads to field staff understanding the need for pallet management.

Morozoff. Limited.

Previously, we used our own skid between the factory and distribution center, but since it was operated in-house we did not manage receipts and payments for the skid.

It led to cases where there was a shortage of skids during the busy season, while we had skids piled up at the distribution center during the off season.

In addition, some were lost or leaked, thus every two years, about 1,000 new skids were deployed.

However, by using rented pallets and managing receipts and payments with "epal", the staff came to realize that rentals are costly and that if they are not managed properly, they will be an increased cost. I think this had a huge impact.

On the other hand, accurate management is difficult unless all staff, including the field staff, understand the system and operation of "epal" so I think that the issue of penetration among staff has become apparent.

JPR

At the time of onboarding, JPR explained the system and operation to the staff in the field, but I think there are many points that you only comprehend after actually starting operations.

Even if it is a trivial matter, please feel free to contact us if you have any questions. We also have staff specializing in systems, so we will do our best to support you.

I hope that inventory management will be easier and more accurate in the future.

Morozoff. Limited.

If "epal" can be further utilized in the future, I think that the flow of pallets can be better understood in real time, and there is a possibility that pallet shortages and stagnation will be eliminated.

We use it as an inventory management tool for the entire Morozoff. Limited., but I think that it is a great advantage for companies with a large number of bases, where it has the potential for detailed management for each base.

If the pallets equipped with RFID (automatic identification technology which is ever growing in popularity), and "epal" work together, it will be possible to further reduce the labor required for voucher management and data input, which will improve work efficiency. In addition, if the information of the pallet and the loaded products are linked, a first-in first-out workflow can be created, which is effective for inventory management. I expect JPR to further evolve the "epal" system.

JPR

Since "epal" is a system that was born from the voices of people in the field, we will continue to work to improve usability in the field.

The idea of creating a system that can manage not only JPR rented containers but also customer-owned logistics containers came from the field. We will continue to feed back the opinions of our customers to the development team and improve the system.

*RFID (Radio Frequency IDentification) is an epoch-making information technology that uses the Internet to enable people and things to be identified and managed with a small wireless chip. IC cards such as Suica and Edy (contactless payment cards) are examples of high-profile RFID applications.